Arco Professional Safety Services News

TRAINING FOR CONFINED SPACE WORKING – ARE YOU FULLY COMPLIANT?

Brian Grunes, Arco Professional Safety Services Confined Space training expert offers guidance on the risks of confined space working and the upcoming changes to the City & Guilds training accreditation

Q. What kind of working situation could pose a confined space risk?

The existence of confined spaces in some workplaces can be reasonably easy to identify and understand. Tanks, vessels, sewers among others are known to be confined spaces to people working in those environments; however, the existence of confined spaces in commercial or non–industrial premises are less well known. Service ducts, lofts and void spaces, plant rooms or poorly ventilated rooms can be confined spaces too and often found in commercial buildings, hospitals, universities and residential dwellings. Some confined spaces will also develop during construction, or when work activities such as welding or cleaning is being carried out. These spaces are just as hazardous and demonstrate that systems of safe working must be in place in every environment.

Q. What are the dangers of working in confined spaces?

A significant number of people are killed or seriously injured working in confined spaces in the UK each year. Specified risks include: serious injury due to fire or explosion; loss of consciousness arising from increased body temperature; loss of consciousness or asphyxiation arising from gas, fume, vapour, or lack of oxygen; drowning from an increase in the level of a liquid and asphyxiation arising from a free-flowing solid or being unable to reach a respirable environment. These risks occur across a wide range of industries, including manufacturing, utilities, maritime, construction, offshore and agriculture. Those at risk include workers in the confined space itself and those who may have to try to rescue them when things go wrong. Despite legislation and health and safety measures, confined space working poses a very high risk and it’s important to ensure that the right people have the correct skills and capabilities for the roles they undertake. Training is just one part of ensuring the safety of people working in confined spaces.

Q. What should you consider when preparing to undertake confined space working?

Once you have identified that work will be undertaken in a confined space it is important that the right controls are put in place. The Approved Code of Practice (ACoP) L1010 Safe Working in Confined Spaces provides details on the relevant provisions that must be considered. This includes an initial assessment as to whether the work required could be completed without the need to enter the confined space. If that is not possible, then taking the necessary precautions for safe working in a confined space, which will include training, supervision, ensuring safe access and egress, testing and monitoring the atmosphere before and during the procedure, having a reliable communications system in place and suitable equipment for the job. In the event of an accident you would need to show you have followed the code or complied with the law in some other way otherwise a court will find you at fault.

Q. What kind of training is needed for confined space working and who needs it?

Confined space training is essential for those managing or supervising confined space teams as well as those working in confined spaces and for rescue and recovery teams. Confined space training options range from Confined Space Awareness training, through Low, Medium and High-Risk courses, plus Rescue Management and training covering the selection and maintenance of equipment involved in safe confined space working, such as gas monitors, breathing apparatus and personal protective equipment. If the risks are assessed to be too high or the job too complex for in-house teams, you should consider outsourcing jobs to confined space services experts. The confined space courses offered by Arco Safety Services are mapped against a range of National Occupational Standards (NOS) used by a range of Awarding Organisations (AOs) to produce assessment criteria for the level of qualification required. The main AO that we use for confined space is City & Guilds, who offer a suite of associated qualifications.

Q. There’s been some updates to the City & Guilds accreditations – could you explain what these are?

Following the changes made in 2020 to the National Occupational Standards (NOS) for Confined Spaces, City & Guilds reviewed their Confined Space qualifications and announced a new suite that became available earlier this year. The new 6160 suite of qualifications replace the existing 6150 ones which will continue to be available until 31st December.

Q. I’ve only just completed my City & Guilds 6150 (or: My City and Guilds 6150 Qualification is still valid for a year), do I need to complete the new qualification immediately?

These new qualifications are available now, with the existing qualifications (6150) being available until 31st December 2021. For anyone holding a current 6150 qualification, it will remain valid for three years from its completion so there’s no need to undertake the new 6160 qualification until it’s due to expire.

Q. Where are your training facilities?

Training can be delivered at our national specialist training facilities or at customer’s premises, utilising either their facility (based on a set criteria) or one of our mobile confined space units.

Arco Professional Safety Services currently has four specialist Safety Centres located at Enfield (South), Stafford (Midlands), Warrington (North West) and the newly-opened Linlithgow (Scotland). These centres are purpose-built facilities that have been specially designed to simulate real life hazards in a controlled environment.

Q. What are the training options at the moment, given current restrictions due to Covid-19?

Continuing to provide practical skills is essential in critical and high-risk industries and so Arco Professional Safety Services has adapted operations at its training centres to provide attendees with a safe learning environment and the reassurance they need to join safety critical training programmes. This includes new precautions, such as pre-start COVID questionnaires, non-contact body temperature checks, staggered break times to minimise unnecessary people movement and mixing and the use of larger rooms equipped with enclosure screens to ensure adequate social distancing. Arco Professional Safety Services has also launched a number of video conference options including a Confined Space Working Awareness half-day course and blended learning options, mixing online theory with practical learning.

Q. Do you offer any other kind of assistance for confined space working or emergencies?

Our services team provide confined space practical advice and service delivery in the areas of supervision, rescue, inspection, surveying & mapping, and cleaning & maintenance. Arco Professional Safety Services also provides 24/7 dedicated standby rescue teams and specialist confined space rescue consultants who are highly experienced in confined spaces safety and provide both 'entry' and 'non-entry' rescue solutions to businesses.

For more information on Arco’s Professional Safety Services Confined Spaces services, please visit

Confined Spaces services, please visit

https://www.arcoservices.co.uk/home/confined-space

Arco Professional Safety Services News

Press Release Originally Released in January 2021

Arco Professional Safety Services unveils new Safety Centre in Linlithgow

£500,000 Northern training facility has opened

UK safety expert Arco Professional Safety Services has unveiled its new Safety Centre in Linlithgow, Scotland, expanding its presence in the UK and supporting the safety and welfare of businesses in the region. The new Safety Centre will provide delegates with realistic, practical training that simulates real-life hazards in a controlled environment.

Ideally located between Glasgow and Edinburgh, the new centre offers purpose-built training facilities for multiple high-risk working environments including:

- Working at Height

- Confined Spaces

The centre boasts facilities ranging from a 20-metre-high outdoor mast for Working at Height Training, to an internal confined space training labyrinth including more than 30 metres of traverse capability and a variety of entry points. With a suite of fully equipped training rooms the centre can also accommodate both large and small groups for training, seminars and meetings, including health and safety training, respiratory training and face fit testing.

Arco Professional Safety Services recognises the importance of training delegates in a safe but realistic working environment. Training is relevant and learning in this way is identified as a requirement in the Provision and Use of Work Equipment Regulations 1998 (PUWER).

The additional centre forms part of Arco’s growth strategy, bringing the number of its specialist training centres up to four, with further safety centres in Enfield in the South, Stafford in the Midlands and Warrington in the North West.

Jamie Sadler, Commercial Director, Arco Professional Safety Services, commented on the launch of the Northern Safety Centre: “You can prepare for the risks you know about. But what about those you don’t? We’re on a mission to bring about real, long-term cultural change. The launch is a celebration for all us at Arco because the bigger our geographical presence is; the more organisations we can keep safe.”

To learn more about the new Safety Centre, visit https://www.arcoservices.co.uk/home/northern-safety-centre.

Arco Professional Safety Services News

WORKING AT HEIGHT AND THE IMPORTANCE OF TRAINING

Falls from height are the single biggest cause of workplace deaths and one of the main causes of major injury within the workplace. Steve Dawson, working at height expert at Arco Professional Safety Services, explains the importance of training for working at height and having the right equipment.

The most tragic consequences of not providing the right training and protective equipment to your work force, can be serious injury or even the death of an employee. In 2020/21, 35 fatal injuries were due to Falls from a height, accounting for 25% of all worker deaths over the year. [1] Add to this the 17 deaths caused from ‘Struck by moving’ (including flying/falling objects) statistics – which can often be related to Working at Height – and there continues to be a serious need for education and training.

Employers are bound by law under the Work at Height Regulations 2005 and are required to eliminate or reduce the risks when working at height. Anyone in control of any work at height must ensure that the work is properly planned, and carried out by people who have sufficient skills, knowledge and experience. This must include appropriate training at all levels, from project managers to end users of critical safety equipment e.g. PPE & Rescue equipment.

In the first instance, employers should assess the risk and consider alternative methods for getting the job done without the need for working at height. However, if that is not practical, then it is their legal duty to make sure the requirements of the Regulations are met and their employees are kept safe. As one of the most common high-risk business environments, it is essential that people receive the proper training before commencing work at height. Training solutions can either be tailored to a particular need or provided through a number of off-the-shelf courses. Highly experienced trainers will work with you on or off-site to provide training at all levels of your business.

Why is training so important?

Most would agree that incidents on site start at the risk assessment and planning phase. The end user of PPE doesn’t stand much chance of staying safe if work planners do not have sufficient knowledge and experience to appropriately mitigate the risk in the first instance. Appropriate training at this level is vital and should help mitigate risk but can also result in a more efficient safe system of work.

If personal fall protection is required, it can only protect the worker if they are competent in its use, aware of why they must use it, and therefore properly trained. Experienced instructors can simulate realistic working environments and provide advice on the correct equipment to use, and how to use it, together with practical training which can be taken back to real life situations.

New and existing industry/trade bodies are acutely aware of the importance of standardised, quality training delivery for Working at Height. The recent release of the Rooftop Safety Training Standard by the Construction Industry Training Board (CITB) is just one of many examples of industry bodies driving much needed and positive change in their respective sector. There is also an abundance of equipment now available from manufacturers which provides employers with cost effective, practical options to keep workers safe. Training is paramount to ensure end-users understand the advantages and limitations of this equipment when used in their work environment.

Continuing importance of training

Between April and June last year, 32 million working days were lost to COVID-19 related absences. Redundancies, movement restrictions and fluctuating guidelines have made it difficult for organisations to provide their workers with training. As restrictions are lifted and the country moves towards a return to ‘normal’, many businesses are trying to catch up but are struggling to keep up with training requirements.

Reduced training and a reduction in task-based activity will undoubtedly result in skills fade. The possible consequences in high-risk industries such as working at height, are plain. To maintain skill levels in industry, business leaders are looking at new ways of achieving this. Alongside contingency plans and ‘back to work’ responses, health and safety training must be boosted to ensure that a restructured workforce can cope with high-risk environments and inevitable skill gaps that can occur.

It’s vital that this training provides workers with the right balance of knowledge and practical skills to be able to deliver their work safely. It is all too tempting for companies to provide their workers with theory only training when social distancing and movement restrictions are in place; however, the shortfall in practical skills could have severe consequences. This is not to say that there is no place for training in the virtual world, there is a balance to be struck where it is safe to do so. The workforce needs the confidence to manage their daily tasks safely but also not to be exposed to the increasing risk of contracting COVID-19 by receiving training in the normal classroom setting. Arco Professional Safety Services has launched several video conference courses and are developing Virtual Reality tools to help organisations keep its workforce safe whilst also maintaining the recommended social distances measures on our practical training courses during COVID-19.

https://www.arcoservices.co.uk/training/course-finder/video-conference-training

Source:

[1] https://www.hse.gov.uk/statistics/pdf/fatalinjuries.pd

Arco Professional Safety Services News

A forging company has been fined after an employee suffered a fatal injury when he fell from height from a mobile tower scaffold.

A Stokes Group Limited employee George Clifford was fatally injured at the company site on Cochrane Road, Dudley, West Midlands, after falling from a tower scaffold whilst dismantling a Eumuco 2000 Tonne Forging Press, Dudley Magistrates’ Court was told. The incident happened on 19 June 2019.

The HSE’s investigation found the company had failed to have a safe system of work in place for the dismantling of the forging press and did not provide information, instruction and training for the task. The mobile scaffold tower was erected without suitable and sufficient measures namely guard rails to prevent a person falling a distance liable to cause injury.

Stokes Group Limited of Cochrane Road, Holly Hall, Dudley, West Midlands pleaded guilty to breaching Section 2(1) of the Health and Safety at Work etc Act 1974. The company was fined £50,000 and ordered to pay costs of £2,885.20.

Speaking after the hearing, HSE Inspector Karen Sweeney said. “The incident could have been prevented if the work had been properly planned, risk assessed and a safe system of work put in place for the dismantling of the forging press. When devising a safe system of work, consideration should have been given to the selection of work equipment for work at height and whether a mobile tower scaffold was appropriate.

“The incident could also have been prevented had the tower scaffold been erected with suitable and sufficient measures such as guard rails, to prevent a person falling a distance liable to cause injury.”

Article from Safety and Health Practioner online

Arco Professional Safety Services News

Article Originally Released in October 2020

Ben Haughton, technical director at Arco Professional Safety Services, says skills fade may lead to increased risks to health and safety in high risk industries

Everyone has a fundamental human right to go to work each day and come home to their loved ones safely. Nonetheless, statistics show that in the last year the Construction Industry was hardest hit by fatal injuries (40), followed by Agriculture, Forestry and Fishing (20) and Manufacturing (15)1. This in a year of normal work activity.

Ben Haughton, technical director at Arco Professional Safety Services, speaks out about the escalating dangers industries may face as businesses deal with the ongoing fall-out of COVID-19.

Which industries are in danger of becoming more susceptible to workplace risks?

Between April and June this year alone, over 32 million working days were lost to COVID-19 related absences2. In addition, redundancies and fluctuating guidelines have made it increasingly difficult for organisations to provide their workers with training. Movement restrictions, company policies and lockdown have all contributed to a reduction of training over the summer months.

Businesses are doing their best to catch up but with the threat of a second wave and tighter restrictions coming into force, it is hard to see how they will keep up with training requirements. Reduced training and a reduction in task based activity (those who have extended time in furlough) will result in skills fade. The possible consequences of this in the high risk industries of confined spaces and working at height are plain. If we are to maintain skill levels in industry, we need to look at other ways of achieving it.

How can businesses manage rising threats to safety?

Alongside contingency plans and ‘back to work’ responses, health and safety training must be boosted to ensure that a restructured workforce can cope with high-risk environments and inevitable skill gaps that can occur.

It’s vital that this training provides workers with the right balance of knowledge and practical skills to be able to deliver their work safely. It is all too tempting for companies to provide their workers with theory only training when social distancing and movement restrictions are in place however the shortfall in practical skills could have severe consequences.

This is not to say that there is no place for training in the virtual world, there is a balance to be struck where it is safe to do so. The workforce needs the confidence to manage their day-to-day tasks safely but also not to be exposed to the increasing risk of contracting COVID-19 by receiving training in the normal classroom setting. We’ve launched several video conference courses and we are developing VR tools to help organisations keep its workforce safe whilst also maintaining the recommended social distances during COVID-19.

How has COVID-19 impacted training centres?

We understand that managing health and safety risks can be complicated, time-consuming and demand a level of technical expertise – and resources – that businesses may not have internally. COVID-19 shouldn’t stop organisations reaching out for help, equally it doesn’t mean that training should stop. Providing practical skills is essential in high-risk industries and so we have adapted our centres to provide attendees with a safe learning environment and the reassurance they need to join critical training programmes.

We’ve introduced new precautions at all our training centres, such as pre-start COVID questionnaires, non-contact body temperature checks, staggered break times to minimise unnecessary people movement and mixing and the use of larger rooms equipped with enclosure screens to ensure adequate social distancing. Where the physical element is indispensable, in height rescue training, for example, we can still find ways to cut proximity and limit the time spent in close contact with trainers.

As a result of the pandemic has there been anything you’ve had to do differently?

There has been a stark increase in demand for all types of Personal Protective Equipment for healthcare workers and all first line Covid-19 responders, with a particular focus on Respiratory Protective Equipment (RPE). Working with this equipment requires face fit testing and for many, this will be a new procedure, but a critical one, as research has found mask protection can significantly improve with fit-testing and one-to-one training on mask use, providing all correct procedures have been adhered to.3

In normal circumstances our national network of face fit test providers can deliver testing at an organisation's site, dramatically reducing the amount of employee down time. However, during the current situation, our team has also been focussed on supporting the NHS, first line responders and other key workers, providing face fit testing, whilst adhering to social distancing and the revised HSE guidelines for providing this service.

We conduct two forms of face fit testing, qualitative and quantitative, both provide an indication on whether a fit has been achieved, the quantitative test being the more sensitive of the two tests. Matching an individual’s face shape with a compatible mask and teaching wearers how to ensure a tight seal is achieved is significantly helping to protect frontline workers during this period. We are also looking to utilise some of our 44 retail stores as drop-in clinics to support care workers, dentists, ambulance crews etc with face-fit testing.

[i] For further information, visit https://www.arcoservices.co.uk/

Arco Professional Safety Services News

Article Originally Released in March 2021

‘On hearing the phrase “you saved my life” I became instantly dedicated to improving my knowledge around the wellbeing and mental health of people’

Mark Nixon, Senior Health, Safety and Wellbeing Consultant and Trainer at Arco Professional Safety Services, Shares Three Key Areas of Focus for Positive Mental Health and Wellbeing in the Workplace.

I have been a passionate Occupational Health and Safety Professional since 1995, but something changed five years ago. I was fortunate enough to be able to prevent a young individual from committing suicide. On hearing the phrase “you saved my life”, I made a commitment to improving my knowledge around the wellbeing and mental health of the people I work with every day and the employees in my clients’ organisations. I now deliver Arco Professional Safety Services suite of courses to clients and instruct the MHFA Two Day Adult Mental Health First Aid course. The feedback for these courses is breathtakingly positive; quite simply, the courses change lives and save lives.

I have been a passionate Occupational Health and Safety Professional since 1995, but something changed five years ago. I was fortunate enough to be able to prevent a young individual from committing suicide. On hearing the phrase “you saved my life”, I made a commitment to improving my knowledge around the wellbeing and mental health of the people I work with every day and the employees in my clients’ organisations. I now deliver Arco Professional Safety Services suite of courses to clients and instruct the MHFA Two Day Adult Mental Health First Aid course. The feedback for these courses is breathtakingly positive; quite simply, the courses change lives and save lives.

Mental distress across the nation is at an all-time high compared to pre-pandemic levels.1 As individuals face grief, forced isolation, an economic slump and unfamiliar ways of working, we can help organisations make the decisions that will strengthen, rather than harm, an already vulnerable workforce. Beyond the human cost, better mental health support in the workplace can save UK businesses up to £8 billion per year.2 There are three key areas that demand organisations’ attention to support and improve mental health and wellbeing in the workplace: the business, the managers and the individuals.

The Business

The ‘Hierarchy of Controls’ is an approach to risk reduction that has become entrenched in the Occupational Health and Safety (OHS) sector. It aims to provide a consistent structure for managing safety, ensuring effective control measures are put in place to eliminate or reduce workplace hazards. However, mental wellbeing is one of the only areas of health and safety where the 'hierarchy of control' does not apply. At Arco Professional Safety Services, we have developed an alternative hierarchy that better suits the aims, problems and solutions in this critical area. Key principles include:

The ‘Hierarchy of Controls’ is an approach to risk reduction that has become entrenched in the Occupational Health and Safety (OHS) sector. It aims to provide a consistent structure for managing safety, ensuring effective control measures are put in place to eliminate or reduce workplace hazards. However, mental wellbeing is one of the only areas of health and safety where the 'hierarchy of control' does not apply. At Arco Professional Safety Services, we have developed an alternative hierarchy that better suits the aims, problems and solutions in this critical area. Key principles include:

- Prevention is better than cure. Recovery takes far longer than prevention and the costs to individuals' livelihoods and businesses are far greater

- Failing to maintain health and wellbeing increases the likelihood of poorer mental health

- Enhancing and maintaining overall health and wellbeing increases the likelihood of better mental health

The Managers

How much stress a team faces is dependent on factors such as resource availability, workload, corporate culture and the strength of their support system. Managers are ideally placed to help handle employee stress as they have a greater understanding of the people in their team, their roles and the stress risk factors. In as little as one day, we can help managers acquire the knowledge and confidence to manage mental wellbeing proactively. We recommend a ten-point action plan that can help managers support their teams more effectively. Key actions include:

- Carry out Stress Risk Assessments based on the Health & Safety Executive’s (HSE) Stress Management Standards (HSG218) to establish and resolve the causes of stress in the workplace and use the HSE’s ‘Talking Toolkit’ to engage with individuals about the topic and make reasonable adjustments

- For non-work-related stress, managers can use a coaching approach (ask rather than tell) to help employees identify what is causing their stress, why it’s stressful to them, how they can tackle it and where they can go for help and support

- Managers can encourage employees to complete a Wellness Action Plan (WAP), which can be used to promote wellness in already healthy employees and help those suffering or returning from a mental ill-health absence

The Individuals

There are many ways for individuals to manage stress, from guided breathing to decrease stress hormones and lower blood pressure, to understanding the importance of positive psychology. We teach recognised models such as PERMA as part of our mental health training courses to help achieve positive mental wellbeing. PERMA can help increase wellbeing by encouraging individuals to focus on living meaningfully, establishing supportive relationships, accomplishing goals and being fully engaged with life. Another key aspect of positive psychology is resilience, defined as the ability to cope with and recover from adversity.

Individual resilience will differ from person to person and throughout a person’s lifetime. It is not a fixed trait; it can be taught and developed over time with experience. Dr Lucy Hone, researcher and resilience expert, outlines three key traits of resilient people:

- Resilient people understand that bad things happen to everyone

Every life will come with ups and downs and understanding this is critical to a balanced response to fortune and tragedy - Resilient people can focus their attention skilfully

Being able to view a situation ‘as-it-is but not worse than it is,’ is a vital skill for resilience and mental wellbeing. In addition to the things that may not be going so well, individuals can focus their attention on extracting the positives, otherwise termed as ‘benefit finding’. We recommend individuals ask themselves, ‘what has gone well today and what is still right with me, others and the world?’ - Resilient people ask if what they are doing is ‘helping or harming?’

We encourage individuals to identify their unhelpful thoughts, self-talk and behaviours and choose more helpful, realistic and empowering alternatives

Ultimately, mental health is not only a major issue in the workplace, but a major opportunity to take stock and ensure we are doing everything we can to protect the wellbeing of our colleagues. Five years ago, a near-tragedy cemented my belief that with the right support in place, positive mental health and wellbeing can be achieved and sustained.

Mark Nixon is a Senior Health, Safety and Wellbeing Consultant and Trainer at Arco Professional Safety Services. Arco Professional Safety Services offers specialist courses including Mental Health First Aid, Mental Wellbeing Awareness and Stress and Mental Wellbeing for Managers. Its highly experienced trainers can help build bespoke programmes to meet client needs, whether that means delivering training on the client’s site or at one of its national safety centres. The expert in safety can also provide training online via its specialist video conference service developed during the COVID-19 pandemic to ensure businesses can continue training while maintaining social distancing.

For more information on the mental health and wellbeing training courses available, visit the dedicated course finder at Arco Professional Safety Services. Alternatively, to contact Arco Professional Safety Services call 0330 390 0822 or email info@arcoservices.co.uk.

Sources:

2 https://www.mentalhealth.org.uk/statistics/mental-health-statistics-mental-health-work

Arco Professional Safety Services News

News Originally Released in January 2021

Arco Professional Safety Services support Jubilee Sailing Trust with the safe operation of the only sea-going tall ship designed, built and sailed by a mixed-ability crew.

Arco Professional Safety Services has supported the Jubilee Sailing Trust (JST) with free consultancy on Personal Protective Equipment (PPE) and training since 2017. The Trust runs inclusive adventures at sea, including day sails and voyages from its tall ship, SV Tenacious, the only sea-going ship in the world designed, built and sailed by a mixed-ability crew. As a charity, the JST is reliant on donations to run its uniquely accessible ship that can be sailed by a truly diverse crew, including those with disabilities, mental health conditions, long-term health issues and the socially isolated.

Arco Professional Safety Services, like the JST, places the wellbeing and safety of its people at the forefront of its culture and is delighted to help facilitate such a laudable mission by sharing expertise and equipment. Arco Professional Safety Services has focused on essential working at height training for the charity’s permanent crew, as well as consultancy on the equipment used, storage, inspections and rescue provision. Arco Professional Safety Services has adapted its service to cater for the unique features of the ship that make it accessible to all, from the wheelchair lifts and wide decks to guidance tracks for people with visual impairments.

Ben, a member of JST’s voyage crew who is paralysed from the chest down feared the journey would be too much. “That all changed when I hoisted myself out of my wheelchair up the main mast to the lookout point. When I got to the top absolutely shattered, I heard the whole ship cheer and when I sat there taking in the breath-taking view everything suddenly seemed to click. Gone was the negativity and the constant “I can’t do this” rattling around my head.”

Sally, a Vision Rehabilitation Specialist and member of JST voyage crew, said, “For me physically climbing the mast, jumping off the side of the ship, negotiating the top bunk, and human guiding in sometimes exceptional circumstances; pushed me to extend my own ideas of what I thought I could manage.”

Mike Clayton, Equipment Department Manager at Arco Professional Safety Services, said, “Everyone deserves a safe place to live and work. Arco Professional Safety Services will continue to support the safe operation of the world’s only sea-going accessible tall ship, crucial for delivering inclusive adventures that leave attendees feeling liberated to explore their ability, potential and place in the world.”

Arco Professional Safety Services News

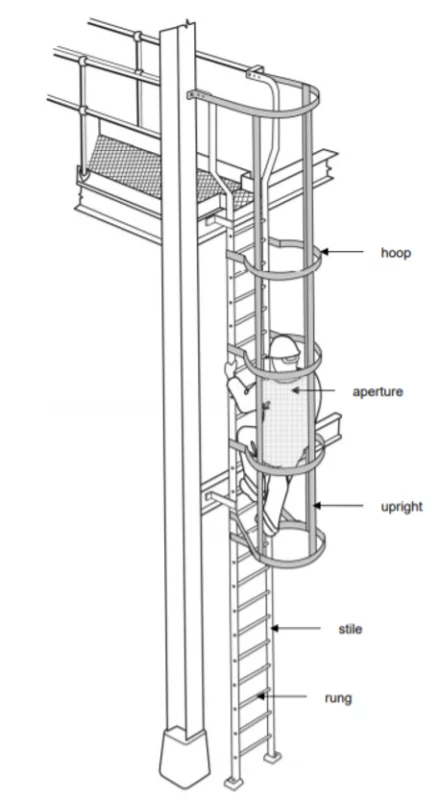

FIxed Ladders fitted with a safety cage: Safe or Unsafe?

By Rob Messenger

With falls from height still one of the leading causes of fatal accidents at work, the industry welcomes two new guidance documents on working safely on portable ladders, released by the Ladder Association and Health & Safety Executive (HSE). Rob Messenger, Work and Rescue at Height Instructor, at Arco Professional Safety Services, looks at the issues of fixed, safety cage ladders and how to mitigate the risks associated with using this type of equipment.

With falls from height the leading cause of fatalities at work – the updated guidance from the HSE and the Ladder Association will be welcomed by safety professionals, site managers, company directors and ladder users alike.

Fixed ladders are common across a multitude of industries within the United Kingdom, as an access method giving many thousands safe access to plant and equipment which is located at height. But is it safe for you, your colleagues, your contractors, or your employees to use caged ladders without any additional measures? Within many industries the use of these ladders without additional fall protection measures has largely been banned. This has been done out of ‘best practice’ rather than due to a legal requirement. However, there are many industries where their use is both frequent and without any fall protection measures in place.

The HSE released a research paper in 2004 titled “Preliminary Investigation into the fall-arresting effectiveness of ladder safety hoops” (Click Here) where they state that, “Various legislative and guidance documents specify ladder safety hoops on fixed access ladders, (alternatively rendered as caged ladders), and give the impression that the purpose of the hoops is to protect workers from falling to the ground or other platform. Previous research has indicated that there is almost a total lack of knowledge in regard to ladder safety hoops.” A quick search with ladder manufacturers brings up comments from many claiming these ladders, “offer a completely enclosed, safe method of access for almost any situation.”

What does the Law say?

The regulations allow the climbing of ladders with safety cages without any fall protective equipment. However, the HSE released a safety bulletin in 2012 titled “Hooped ladders and the use of personal fall-arrest systems” and within this document they say the following:

- “hooped ladders (with or without a personal fall arrest system) may not be effective in safely arresting a fall without injury. As a result, duty holders are advised to review their risk assessments where these ladders are used”

- “HSE does not recommend the blanket removal of hoops from ladders (which would probably increase overall risk), or to prohibit the use of personal fall arrest systems within hooped ladders”

- “hoops alone do not provide positive fall arrest capability; they can provide other safety benefits such as getting on and off the ladder”

How far is too far?

The British Standard BS 5395 Part 3 (1985) recommended that “[…] the height of a ladder should not exceed 6m without an intermediate landing.” This is in contrast with the most recent BS 4211:2005+A1:2008 which specifies 9m. The standard also recommends that ladders over 2m should have a safety cage.

So, what should we do?

The simple answer, as is stated in the HSE 2012 safety bulletin, is that everyone should be attached to some form of fall protection system as research shows that the cages alone will not help a worker during a fall and may even cause more significant injury. However, this is not quite correct as the HSE research found that the effectiveness of some fall arrest systems was ineffective when combined with a caged ladder. We know that falls from height, including low levels, can easily result in fatal injuries and therefore we should try to protect workers who are having to access these ladders but simply putting in a fall arrest system or making workers wear lanyards is not always the best solution.

The simple answer, as is stated in the HSE 2012 safety bulletin, is that everyone should be attached to some form of fall protection system as research shows that the cages alone will not help a worker during a fall and may even cause more significant injury. However, this is not quite correct as the HSE research found that the effectiveness of some fall arrest systems was ineffective when combined with a caged ladder. We know that falls from height, including low levels, can easily result in fatal injuries and therefore we should try to protect workers who are having to access these ladders but simply putting in a fall arrest system or making workers wear lanyards is not always the best solution.

A fall arrest system should have ideally been tested to show its compatibility with a caged ladder or failing that, consideration should be made to remove the cages from ladders once a fall arrest system has been installed.

It is a tricky position for businesses as you will be considering the cost of training, installation of the system, periodic testing of PPE, annual recertification of the safety system, rescue planning for the now suspended worker etc. But all of this will be cheaper than a HSE fine and considerably lighter than the burden of being responsible for an injured worker.

A factor to perhaps consider is the physical fitness and the health of the person climbing the ladder. How many employers have considered the following when assessing aptitude for work at height; Are they comfortable climbing? Used to elevating their heart rate with strenuous activity? Able to hold their body weight and grip a ladder? Do they suffer from a medical condition that could cause a fall such as vertigo, diabetes, epilepsy, low blood pressure etc.?

A construction company recently reported that a 50-year-old male was climbing a caged ladder up a 50m tower crane to reach the control cabin. Whilst climbing the worker felt dizzy and suffered a heart attack, he fell and landed onto one of the landing platforms. The report concluded that having a landing platform every 12 m seemed to have been too much for the worker’s physical abilities, he was going back to work immediately after lunch on a very hot afternoon.

Was he safe? A common response to this question is “he does this all the time, day in day out”, this accident shows that experience doesn’t matter but checking a person’s fitness and health should always be part of the risk assessment.

Rescue and Emergency Planning

The Work at Height Regulations state, “Regulation 4 (1) Every employer shall ensure that work at height is – (a) properly planned[…]” this includes planning for emergencies and rescue.

Other factors to consider include:

- Competence of those trained to rescue

- Suitability of rescue equipment, e.g. the length of the equipment (this is quite often not taken in to consideration)

- Rescuers ability and knowledge to provide first aid post rescue

- Communication with emergency services prior to commencing rescue. If in a remote area post codes are not always useful and ‘What 3 words’ is not always reliable as it relies on good and accurate signal, so having a location identified in the method statement prior to the rescue is essential

- Number of persons trained in rescue. (What if the one person rescue trained is the person who is unwell, injured or has fallen?)

It is worth noting that not all firefighters or stations are trained for nor are they equipped for a work at height rescue. This is the same for the ambulance crew who also have a 27kg bag to get to the patient.

Summary recommendations

Cages/hoops on ladders are a common method of access to everyday workplace platforms, but have been considerably relied upon to arrest and make safe the fall of a worker to which they have been shown to offer no assistance and in fact could cause more injury. The HSE do not require cages/hoops to be removed from ladders nor do they demand a fall arrest system to be used.

The HSE simply recommends that you provide some form of compatible protection for workers on fixed ladders and this can be achieved by working with a reputable fall protection company.

Always make sure the fall arrest system that you use is compatible for a caged/hooped ladder, is regularly inspected, and your staff are fit, trained and competent to access the ladder.

Finally, ensure that you have planned for an emergency/rescue. Rescue equipment is readily available and ensure staff are trained in its use.

Image ref: https://www.hse.gov.uk/research/rrpdf/rr657.pdf

Arco Professional Safety Services News

On Her Majesty’s Safety Service

- Arco Professional Safety Services delivers secret agent to London – safely

- Arco Professional Safety Services behind the dramatic stunt at the London Eye

Dressed in tuxedo and bowtie, Steve Dawson from Arco Professional Safety Services was pictured climbing a ladder below one of the pods on the Lastminute.com London Eye yesterday morning, ahead of the film premiere of Britain’s most famous secret agent at the Royal Albert Hall.

Dressed in tuxedo and bowtie, Steve Dawson from Arco Professional Safety Services was pictured climbing a ladder below one of the pods on the Lastminute.com London Eye yesterday morning, ahead of the film premiere of Britain’s most famous secret agent at the Royal Albert Hall.

As experts in safety and working at height, Arco Professional Safety Services provides consultancy, training, services and equipment to manage the most complex and high-risk, high-hazard scenarios, making the team perfectly placed to undertake this stunt at one of London’s most recognisable and iconic landmarks.

Steve Dawson, Work at Height Training Manager at Arco Professional Safety Services, said: “It’s been a real privilege for Arco, as the UK’s leading safety company, to partner with the team at the London Eye to deliver this exciting event, safely.

“Working at height is what we are trained to do and to demonstrate our skill and expertise, working with the lastminute.com London Eye, is testament to the trust that the organisers have put in us.”